Manufacture of hydromechanical equipment

In the heart of the Savoie region, our team designs hydromechanical equipment that is internationally recognized for its quality and reliability. The combination of our qualified staff and our high-performance machinery enables us to cover and control every stage of the manufacturing process, while maintaining the highest standards.

Made in France

Our products are made exclusively in France, in our workshops in the heart of the Alps.

Made-to-measure

Our teams will work with you to manufacture customized equipment, adapted to the specific requirements of your project.

High quality

Thanks to our expertise, we can guarantee the high quality of every product in our range.

Laser & Folding

• Cutting of steel and stainless steel up to 25 mm thick, with material traceability guaranteed by the supply of 3.1b certificates (CCPU).

• Bending capacities up to 500 tons, rolling and bending.

• Bending capacities up to 500 tons, rolling and bending.

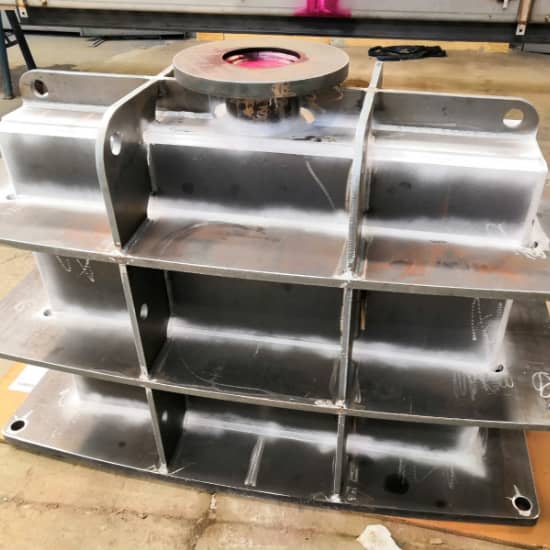

Boilermaking & Welding

• Boilermakers experienced in assembling steel or stainless steel parts of any thickness.

• Verification of parts before and after welding by geometric checks (dimensional, flatness, alignment).

• Qualified welders: compliance with welding specifications drawn up by the design office in accordance with European standards (DMOS, QMOS, QS), with verification of welding procedures.

• In-house non-destructive dye penetrant testing.

• COFREND2-certified inspections on request: penetrant testing (PT), magnetic particle inspection (MT) and ultrasonic testing (UT).

• Verification of parts before and after welding by geometric checks (dimensional, flatness, alignment).

• Qualified welders: compliance with welding specifications drawn up by the design office in accordance with European standards (DMOS, QMOS, QS), with verification of welding procedures.

• In-house non-destructive dye penetrant testing.

• COFREND2-certified inspections on request: penetrant testing (PT), magnetic particle inspection (MT) and ultrasonic testing (UT).

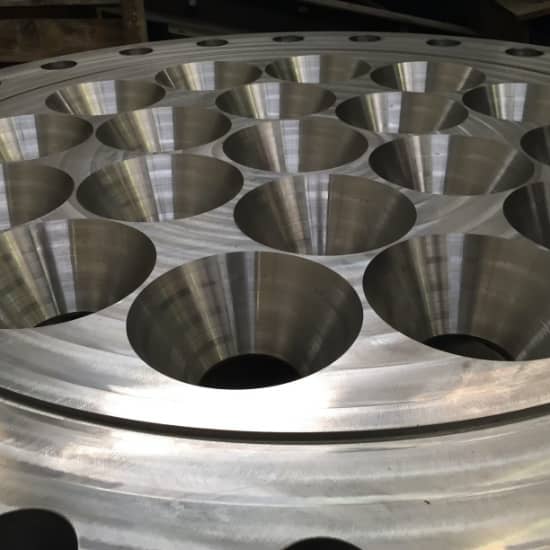

Machining & Surface treatment

• Turning and milling capabilities for small and large parts.

• Verification of parts after machining by dimensional and surface control using calibrated measuring equipment.

• ACQPA-certified anti-corrosion coating (type IM2) including shot-blasting with visio-tactile comparator, primer and epoxy finish.

• Supply of an ACQPA file on request: ACQPA level 2 certificate for applicators, atmospheric control of the booth using a thermo-hygrometer (dew point), control of wet and dry thicknesses.

• Passivation of stainless steel structures.

• Verification of parts after machining by dimensional and surface control using calibrated measuring equipment.

• ACQPA-certified anti-corrosion coating (type IM2) including shot-blasting with visio-tactile comparator, primer and epoxy finish.

• Supply of an ACQPA file on request: ACQPA level 2 certificate for applicators, atmospheric control of the booth using a thermo-hygrometer (dew point), control of wet and dry thicknesses.

• Passivation of stainless steel structures.

Assembly & Testing in-house

• In-house assembly according to procedure, drawings and detailed bill of materials.

• Maneuverability tests.

• Pressure tests (1.5 x PN) in accordance with NF EN 12266.

• Tightness tests (1.1 x PN) in accordance with NF EN 12266.

• Use of a 240 bar hydraulic power unit and calibrated measuring equipment for pressure and tightness tests.

• Maneuverability tests.

• Pressure tests (1.5 x PN) in accordance with NF EN 12266.

• Tightness tests (1.1 x PN) in accordance with NF EN 12266.

• Use of a 240 bar hydraulic power unit and calibrated measuring equipment for pressure and tightness tests.

Packaging & Shipping

• Customized packaging (ISPM15 wooden crates, SEI packaging).

• Mastery of transport logistics, whatever the size of the parts.

• National transport (from pallets to special convoys).

• International transport (export documents, documentary credits).

• Mastery of transport logistics, whatever the size of the parts.

• National transport (from pallets to special convoys).

• International transport (export documents, documentary credits).

Assistance with on-site assembly

• Operating procedure for on-site positioning and adjustment of equipment.

• Dimensional and geometric checks of the installation.

• Assistance to installation teams during handling, assembly and adjustment phases.

• Assistance with dry and wet tests and adjustments.

• Mode opératoire pour mise en position et réglage sur site des équipements.

• Dimensional and geometric checks of the installation.

• Assistance to installation teams during handling, assembly and adjustment phases.

• Assistance with dry and wet tests and adjustments.

• Mode opératoire pour mise en position et réglage sur site des équipements.

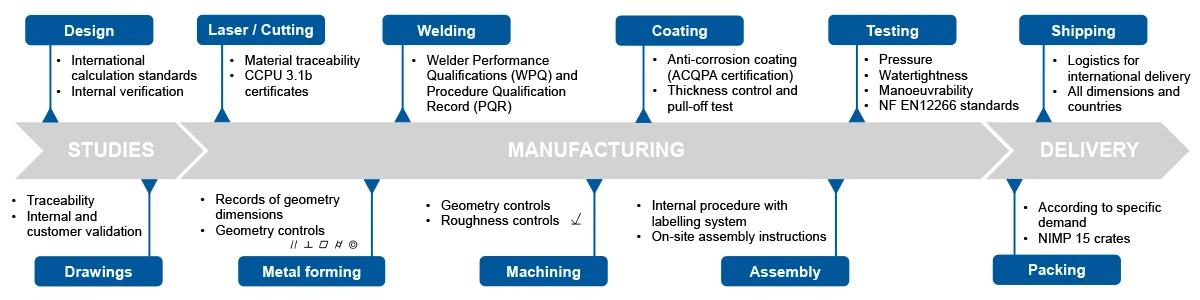

Quality process

Approvals

For domestic water collection plants

Attestation de Conformité Sanitaire (ACS).

Products benefiting from this certificate are :

• Gate type 100

• GateType 100 M5

• Wall-mounted gate

• Stoplog gate

• Weir gate

For pressurized equipment

CE marking. CE certification by an approved agency in accordance with European Directive 97/23/EC.

Welding qualifications :

• Production of welding specifications

• Qualified welders (QS)

• Welding procedure qualification (QMOS)

A daily team of experts at your service

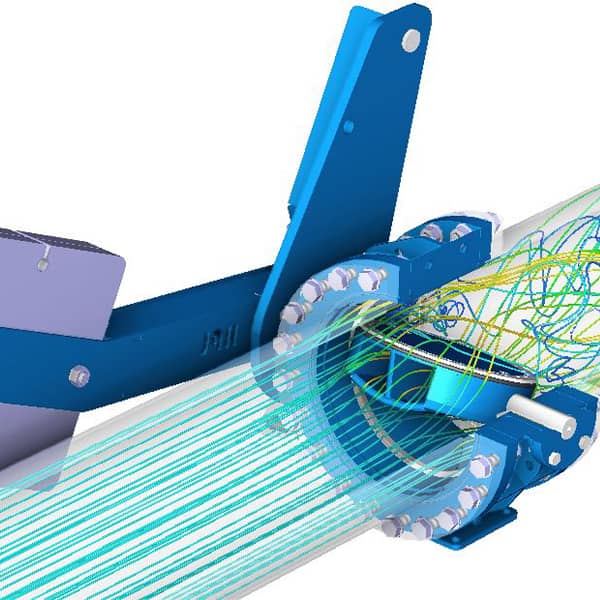

A design office to support your project

HPL Engineering designs standard and customized hydromechanical equipment, adapted to the technical specifications of each project. To do this, our team applies the sizing criteria of international calculation codes.

Hydromechanical equipment made in France

We manufacture all our hydromechanical equipment in France, in the heart of the Alps. This enables us to control the entire production chain, and to guarantee a high level of quality and reliability.